"Over engineered" and "over priced" are things people have been known to say about DSX Tuning products. I figured this is a good opportunity to offer some insight into what you're actually getting when you get a DSX product. There are usually a lot of small details you'd never even notice like tactile feel of installation or material compatibility, but it is all there.

My very first fuel pump controller for a MAP sensor system was based on very simple logic. It was intended to be a simple replacement for a Hobbs switch, and it worked. When moving into a more production based option, logic switched over to a microcontroller for the ability to add a prime function on powerup and a little more defined operation (timing, hysteresis). This hardware proved out to work for the most part (minus the fact that Camaros randomly power up the ECM resulting in the automatic priming function being deleted). E38s and E67s functioned just fine with this controller.

Then, a new player entered the arena: the E92. Thinking nothing of it, I sent a couple controllers out for E92 applications, and every single one reported a failure within the first 10 minutes. Digging in a little deeper, it was discovered that a full power cycle of the ECM would kill them instantly. I was stuck.

When something doesn't work, you have to develop a stop gap. The first thing I did was order an E92, flash it to a Corvette OS, and start poking it with a multimeter to see if there was a quick fix to make existing hardware work with a simple hack. The unfortunate reality was the 5V reference line on the E92 actually powers up to 6V for one second, then drops to 5V for the life of the complete ignition cycle. There was also an unknown of whether a huge voltage was feeding back into the ADC as well, but it became apparent the E92 wasn't going to be a quick easy adjustment. An idea had been rolling around for a while to use CAN data, and this event pushed that idea from concept to prototype rapidly.

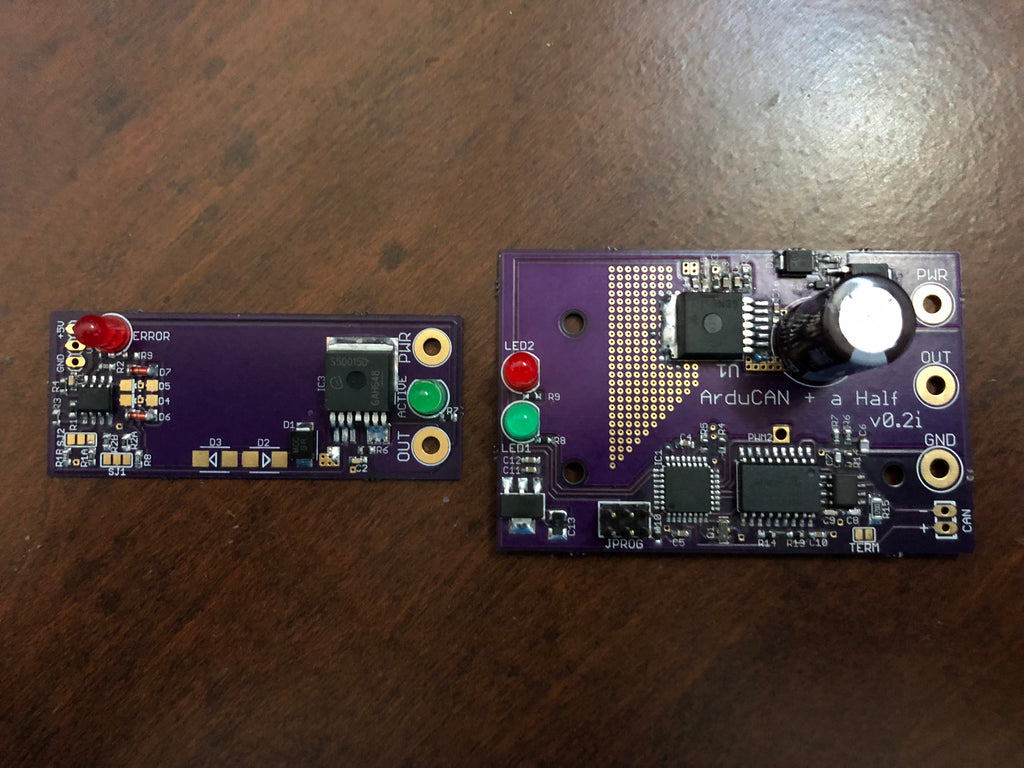

So... The CAN pump controller was born in a very crude way. I had to somehow mate a microcontroller, a CAN interface, and a capable pump driver all into one package. The quickest way to do this was three different components working in unison. I made my own CAN interfaces which served as the gateway board between the microcontroller and the pump driver. Test subjects went out... They worked. They worked really, really well. People appreciated the soft start of the pump and the fact that now, the turn on point was 100% user controlled. People also appreciated the fact that they can now purge the pump completely from inside the car... No need to unplug the MAP sensor and plug into a baro sensor. Now, you could just key on, don't start the engine, and push the gas pedal to run the pump proportional to the pedal position. But there were two problems...

Cost and time. Individual components and mating them together meant each component was expensive. It was also really time consuming and resulted in an assembly time of roughly two hours just for one controller. The right thing to do was just absorb this hard parts and labor cost without passing it on to the customer.

The long term solution was to redesign the MAP sensor method in a way that would withstand torture. To do this, I worked with a friend I've made through the industry. I explained all of the requirements that had to be met and gave a general idea of how I wanted it to function, but I wanted to simplify it all.

It got done. No more coding, no more microcontroller, 100% solid state operation complete with hysteresis and status LEDs, and to top it off... no more external fusing because now, a high side driver with error detection was in use and consequently could protect itself from turning into a small ignition system while giving a glaring red light to say something is wrong. To top it off, this thing can withstand massive voltage spikes. The controller loses the custom programming option, but ultimately, everything was only seeing one of two turn on voltages, which this board has based on a couple of solder jumper selections. While cost of parts went up slightly, the labor of assembly went down significantly because now, it was just a matter of soldering the wiring harness to the board and potting it out inside a 3D printed enclosure. The overall packaging was definitely an improvement.

However... the CAN controller worked too well to just eliminate it. So now that is consolidated onto one board. Hard parts cost is similar to before, but the labor time will be significantly reduced as it won't have to be completely hand assembled anymore. With status lights, built in thermal protection, and a big factor of safety on the driver, it will be a robust and extremely capable controller for even pumps larger than what I use.

The MAP sensor versions will be entering large scale production soon. Right now, they are all hand assembled. The CAN boards are still going through debugging, but they will make their debut later this year as an upcharged option for any system. The MAP controllers will remain as the standard for every system except the upcoming C7 system (which will ONLY be offered with the CAN controller).

I hope this makes it clear that there's actually significant thought into every aspect of what goes out the door, and I hope it makes you feel a little better when you support DSX Tuning products.